Suzhou Pullwin Auto Technology Co.,Ltd

Building 3, Meijite Industrial Product Expo Center No.1055, East Jinyang Road, Lujia Town Kunshan City

Wendy

0086-159-5093-1259

pullwin@pullwinsz.com

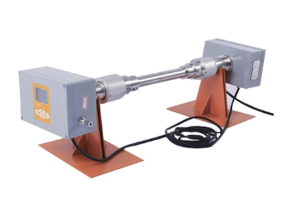

This product is developed based on semiconductor laser absorption spectrosc- opy (DLAS) technology, with integrated design and high degree of integration. The system adopts the in-situ measurement mode which does not need sampling prep- rocessing. It can quickly, accurately and reliably measure various kinds of process g- ases such as industrial process gases and flue gas emissions, provide the best solut- ion for online gas monitoring.

Feature

☆ Integrated design with high reliability.

☆ With multiple technologies, such as semi-

conductor absorption spectrum, digital signal

processing, integrated positive pressure explosion-

proof control, leads to compact design and high reliability for the system. Mean-

while, for explosion-proof applications, with an embedded positive pressure con-

trol module, the system can perform real-time monitoring with explosion-proof

purging positive pressure to meet the requirements of various applications.

☆ The emitting unit integrates an LCD display screen and a keyboard, by which

users can directly carry out calibration and parameter setting on the installation

site. Meanwhile, the system also supports Bluetooth communication. Users can

communicate wirelessly with the analysis system through the WT-200 mobile APP,

convenient and fast.

Specification

Model PW-LA

Optical channel length <15m

Response time <1s

Linearity error ≤±1% F.S.

Span drift ≤±1% F.S./ half year

Maintenance intervals <twice/year ( clean optical window, no request for spare parts )

Calibration intervals <twice/year

Explosive-proof grade Exp xmd IIC T5

IP grade P65

Analog output 2 way 4-20mA,Isolating、Max load 500Ω

Relay output 3ways,24V,1A

Analog input 2way 4-20mA(teperature/pressure compensation)

Digital output RS485/RS232/GPRS

Power supply 24V DC (220V AC optional),<20W

Purge gas 0.3-0.8Mpa Purify instrument air or industrial nitrogen

Environment temp. -30℃-60℃

Installation method In situ or bypass installation