Suzhou Pullwin Auto Technology Co.,Ltd

Building 3, Meijite Industrial Product Expo Center No.1055, East Jinyang Road, Lujia Town Kunshan City

Wendy

0086-159-5093-1259

pullwin@pullwinsz.com

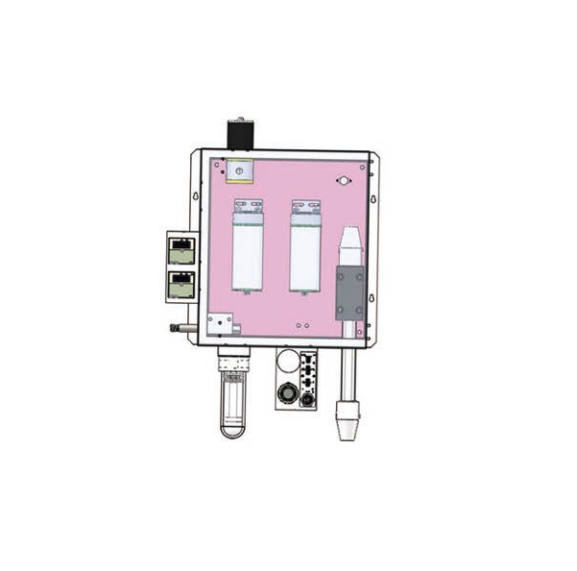

This system can deal with the flue gas with high flow rate and high humidity,remove the gaseous water,acid mist and ammonia gas。It can handle complex gas flow rate up to 5L/min with humidity exceeding 60%v/v( dew point 86℃)

This system is installed in the cabinet to replace the condenser. It do gaseous dehumidification

to ensure the target components(such as SO2,NOX,O2,CO,CO2,CH4) not lost by dissolving

in condensed water or reactiong with escaping ammonia.

Working principle

The working area of the drying tube is divided into two sections : the top half part--rapid

dehumidification in high temperature zone; the bottom half part --deep dehumidification

in normal temperature zone.

The flue gas in high temperature zone passes through a unique deammonizer to get out

the ammonia gas, then passes through the Nafion drying tube to do gaseous dehumidifica

tion, completely retains the components such as SO2,NOX,O2,CO,CO2,CH4 in this process.

After deep dehumidification, the minimum dew point of the fluegas can reach -15℃. The

dry flue gas flows through the dew point alarm before it is used by the analyzer.

The dew point alarm can display the humidity value of current flue gas, when it exceeds

the set value, it will trigger alarm to remind the user or linkage to avoid water into analyze